Watch your vision come to life.

While glass has its own unique set of physical properties, it is an amazingly flexible material for creating new and innovative design, and it is stronger than people realize. We pride ourselves on our ability to collaborate with clients, and to fabricate end products that match their dreams — and exceed their expectations.

For tempered glass products ordered with drilled holes, notches or cut-outs, all fabrication must be done prior to tempering. Since tempered products are under stable pressure, special care must be taken to account for sharp edges or corners and the distance between holes and edges. Vectra’s fabrication processes adhere to ASTM C-1048.

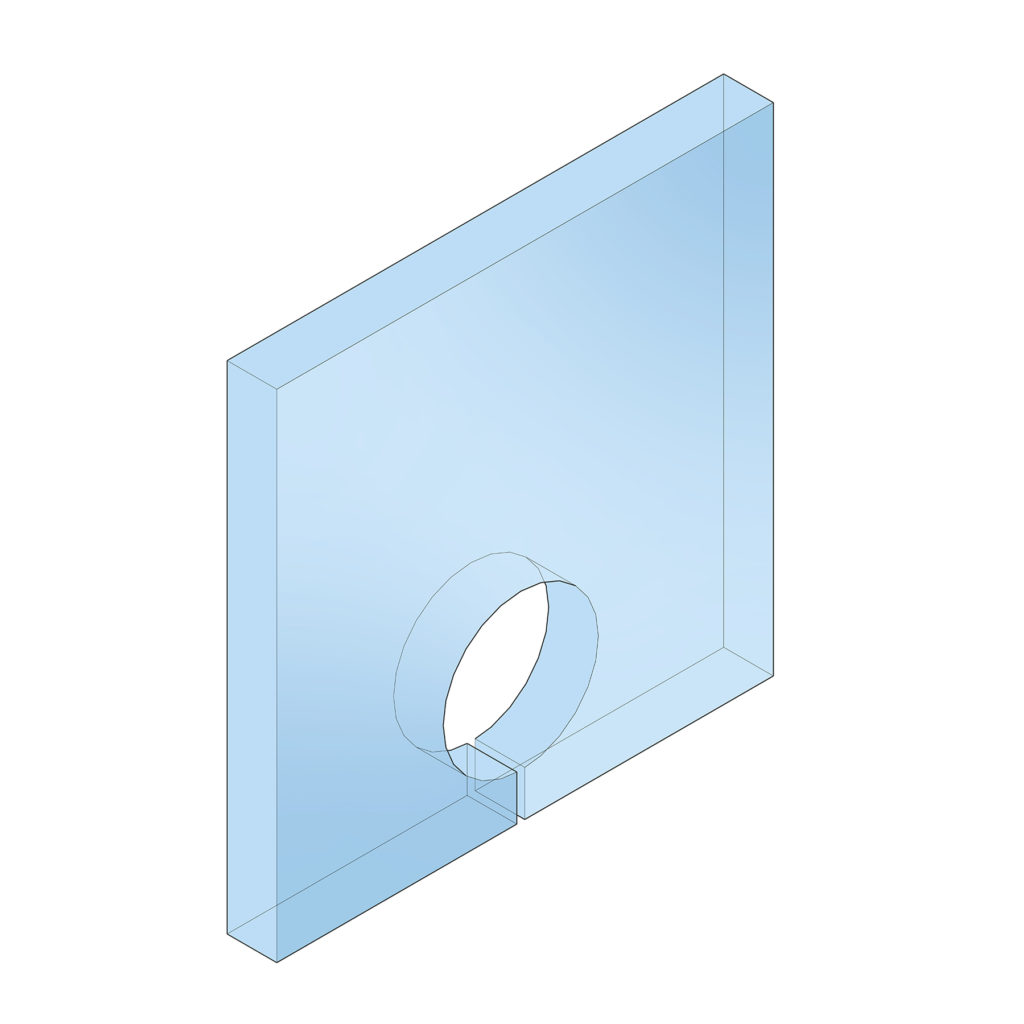

Drilling and Milling

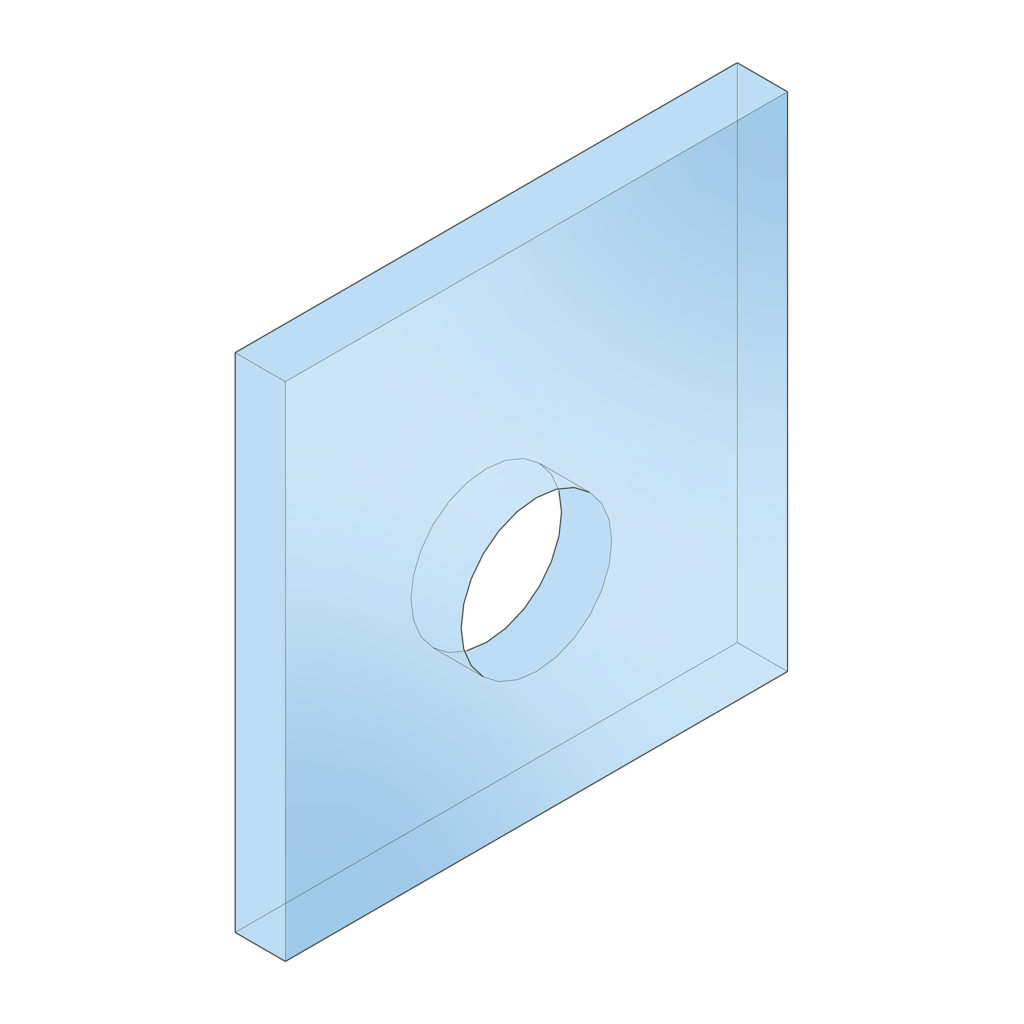

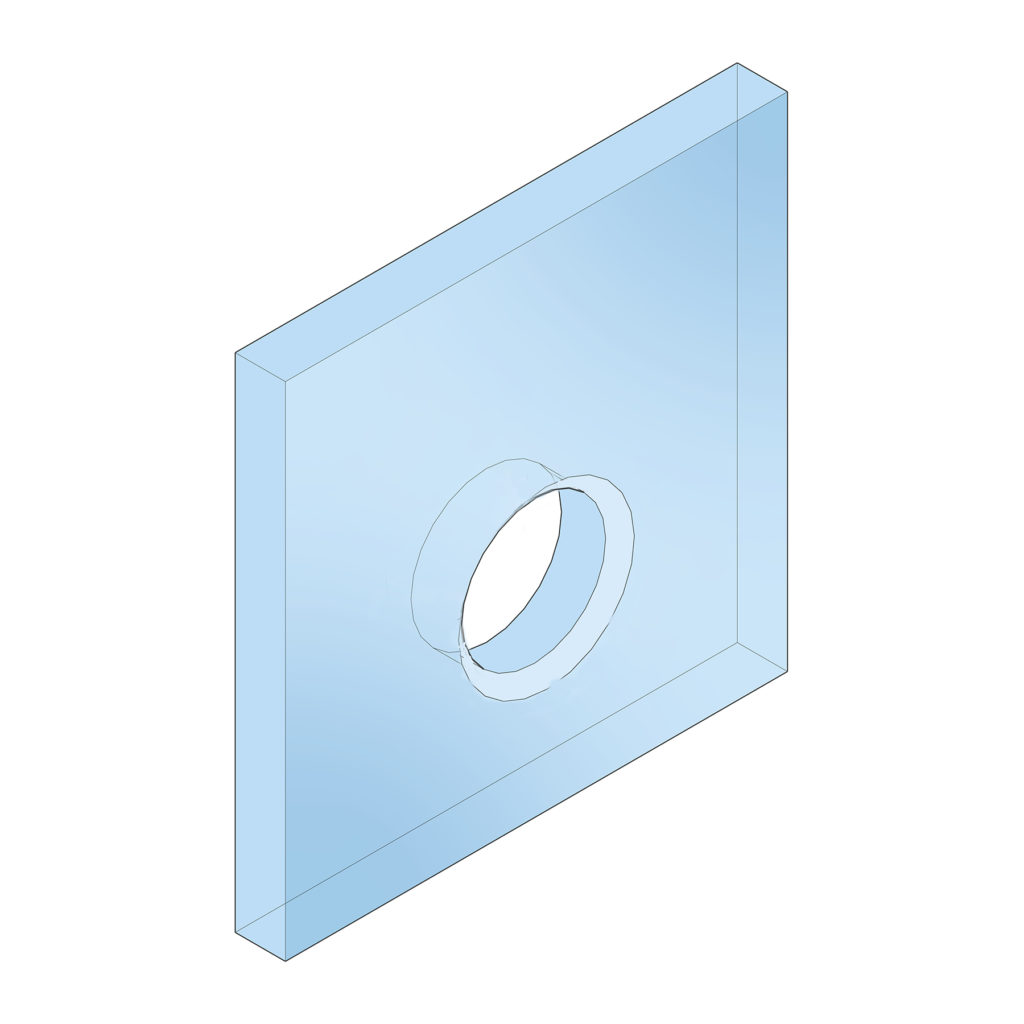

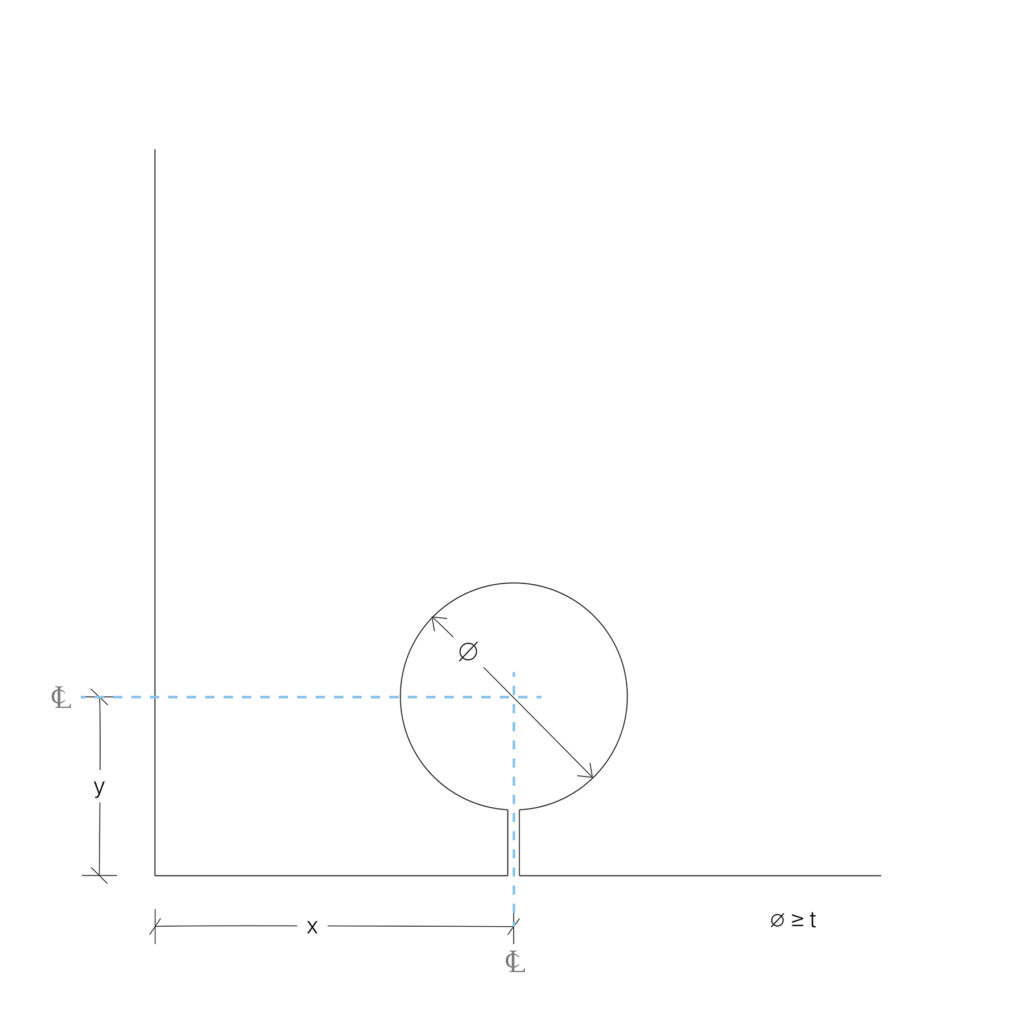

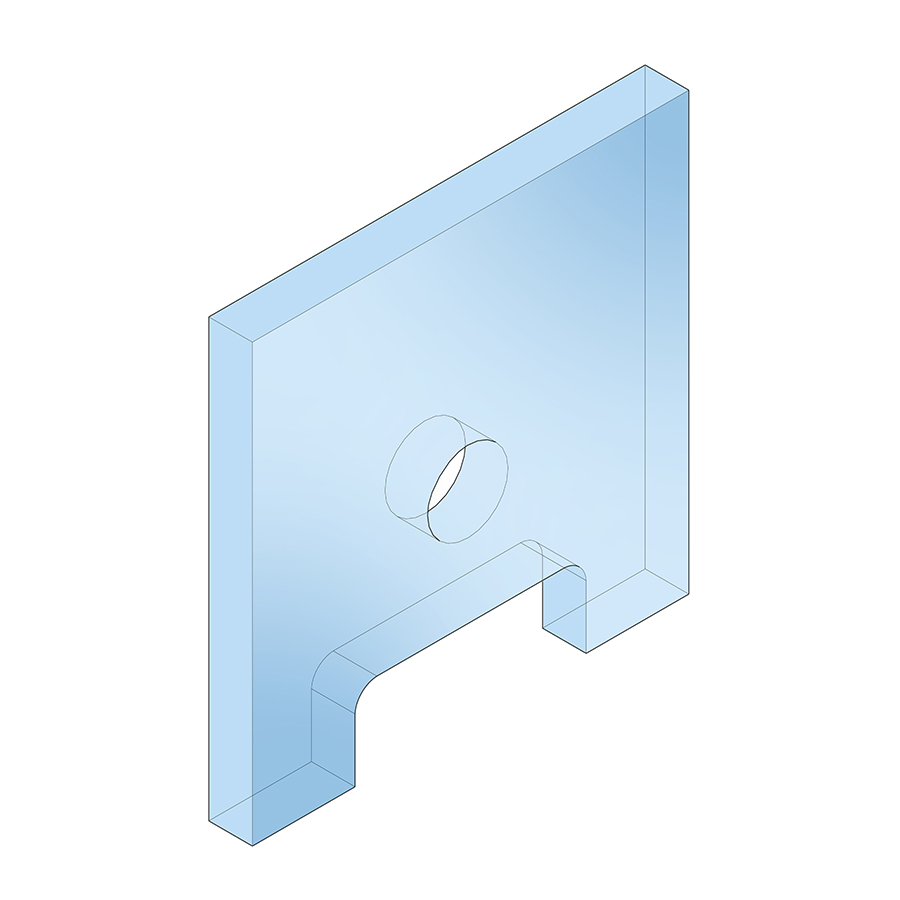

Drilled Holes

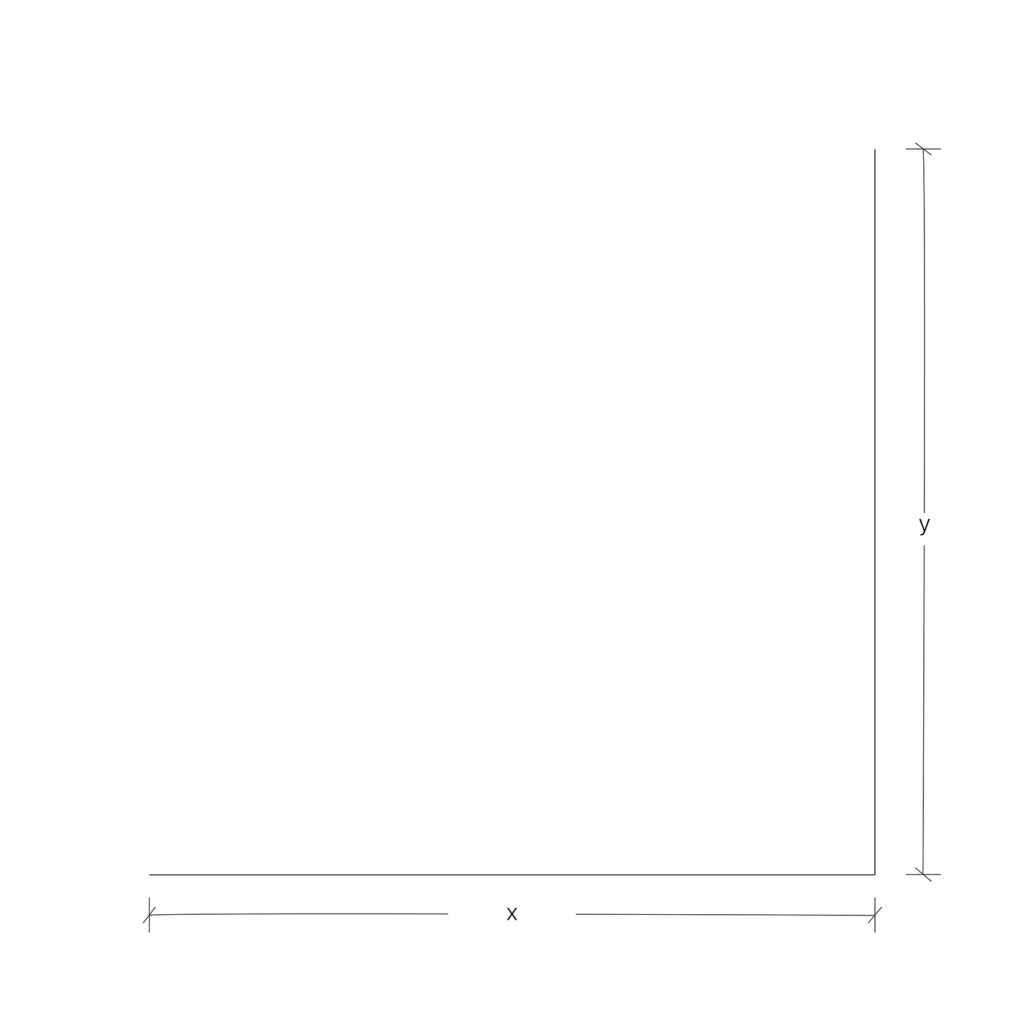

- All holes specified to the center dimension.

- When specifying products that have a surface side, such as coatings, etching, printing, back paint and textures, assume these are on the upper surface, therefore all dimensions need to be drawn “tin side” down.

- Circular holes must have a diameter of at least 1/16” > the thickness (t) of the glass.

- 6 mm (1/4 in.) being the smallest hole allowed.

- If more than one hole, the distance between holes must be 10 mm (3/8 in.) or two (2) times the thickness of the glass, whichever is greater.

- The distance from any edge of the glass to the nearest point on the rim of the hole, must be at least 6 mm (1/4 in.) or two (2) times the thickness of the glass, whichever is greater.

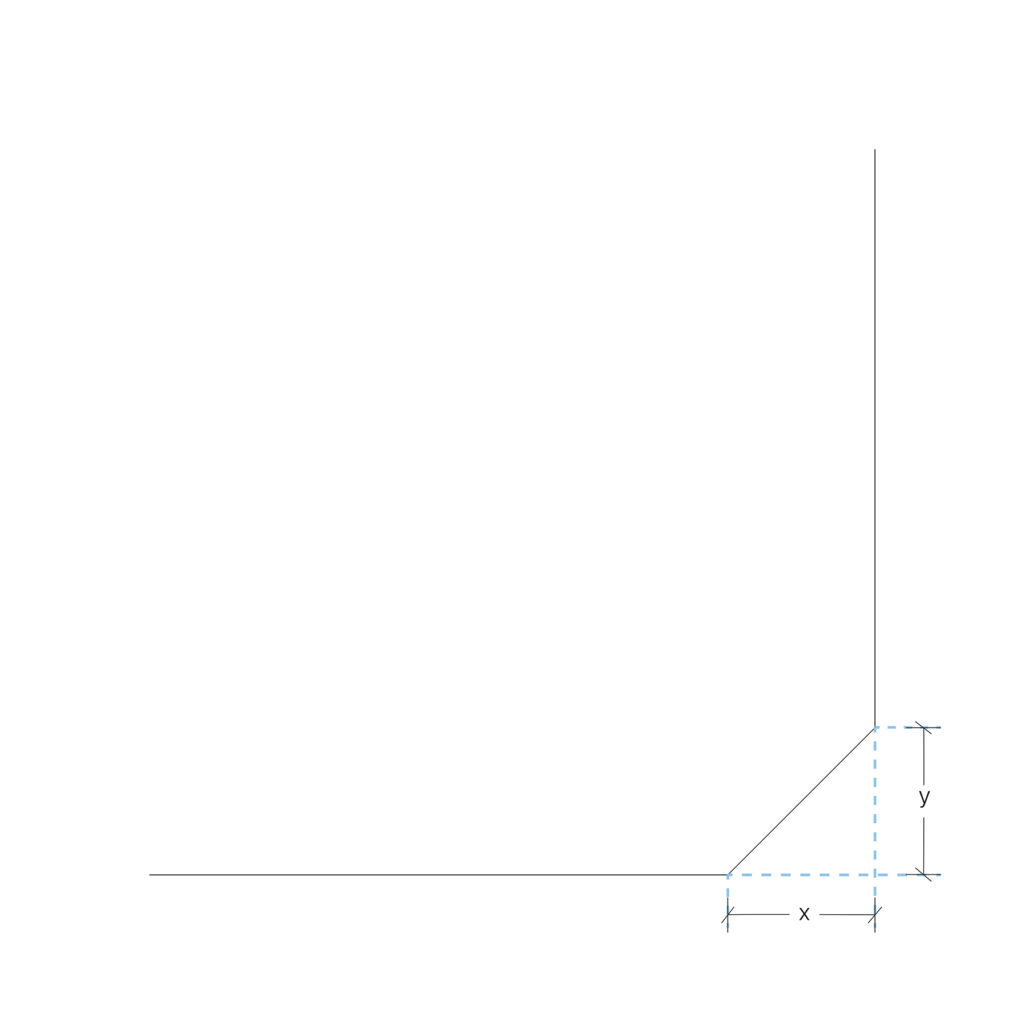

- Holes near corners must be located so that the nearest edge of the hole is at least six and a half (6.5) times the thickness of the glass from the tip of the corner when the corner is 90° or more.

- When the corner is less than 90° or rounded, the minimum distance between the hole and the edge shall be maintained at a minimum of 6 mm (1/4 in.) or two (2) times the glass thickness, whichever is greater. Please note, it may require the hole be located asymmetric with respect to the corner.

- The minimum width of a panel with a hole must be eight (8) times the glass thickness.

- Diameter of hole shall be a minimum of 6 mm or no less than the glass thickness and no greater than one third (1/3) of the panel’s measurement at the narrowest point.

- Dimensional tolerances of hole diameter shall be:

- for hole diameter – ± 1.6 mm (1/16 in.)

- for dimensions of hole center from specified edge – ± 1.6 mm (1/16 in.)

- Chips and flakes at hole edges shall not exceed 3.2 mm (1/8 in.).

- Any given panel/lite of glass has a maximum capacity of ten (10) holes.

| Glass Thickness (in) | Ø – Minimum Diameter (in) | Glass Thickness (mm) | Ø – Minimum Diameter (mm) |

|

|---|---|---|---|---|

| 1/4 | 5/16 | 6 | 8 | |

| 5/16 | 3/8 | 8 | 10 | |

| 3/8 | 7/16 | 10 | 11 | |

| 1/2 | 9/16 | 12 | 14 | |

| 5/8 | 11/16 | 16 | 17 | |

| 3/4 | 13/16 | 19 | 21 | |

| t | equals thickness of glass | |||

| Ø | >= thickness of the glass | |||

| a | > 2.t | |||

| z | >= 6.5.t |

| Glass Thickness | 1/8″ (3mm) | 3/16″ (5mm) | 1/4″ (6mm) | 3/8″ (10mm) | 1/2″ (12mm) | 3/4″ (19mm) | General Rules |

|---|---|---|---|---|---|---|---|

| Diameter of Holes | 1/4″ (6mm) | 1/4″ (6mm) | 1/4″ (6mm) | 3/8″ (10mm) | 1/2″ (12mm) | 3/4″ (19mm) | Ø >= 1/4″ (6mm) or t |

| Distance from Rim to Edge of Glass | 1/4″ (6mm) | 3/8″ (10mm) | 1/2″ (12mm) | 3/4″ (19mm) | 1″ (25mm) | 1 1/2″ (38mm) | a >= 1/4″ (6mm) or 2 x t |

| Distance between Rims of Holes | 3/8″ (10mm) | 3/8″ (10mm) | 1/2″ (12mm) | 3/4″ (19mm) | 1″ (25mm) | 1 1/2″ (38mm) | c >= 3/8″ (10mm) or 2 x t |

| Distance from Corner to Rim of Hole | 13/16″ (21mm) | 1-7/32″ (31mm) | 1-5/8″ (41mm) | 2-7/16″ (62mm) | 3-1/4″ (83mm) | 4-7/8″ (124mm) | z >= 6.5 x t |

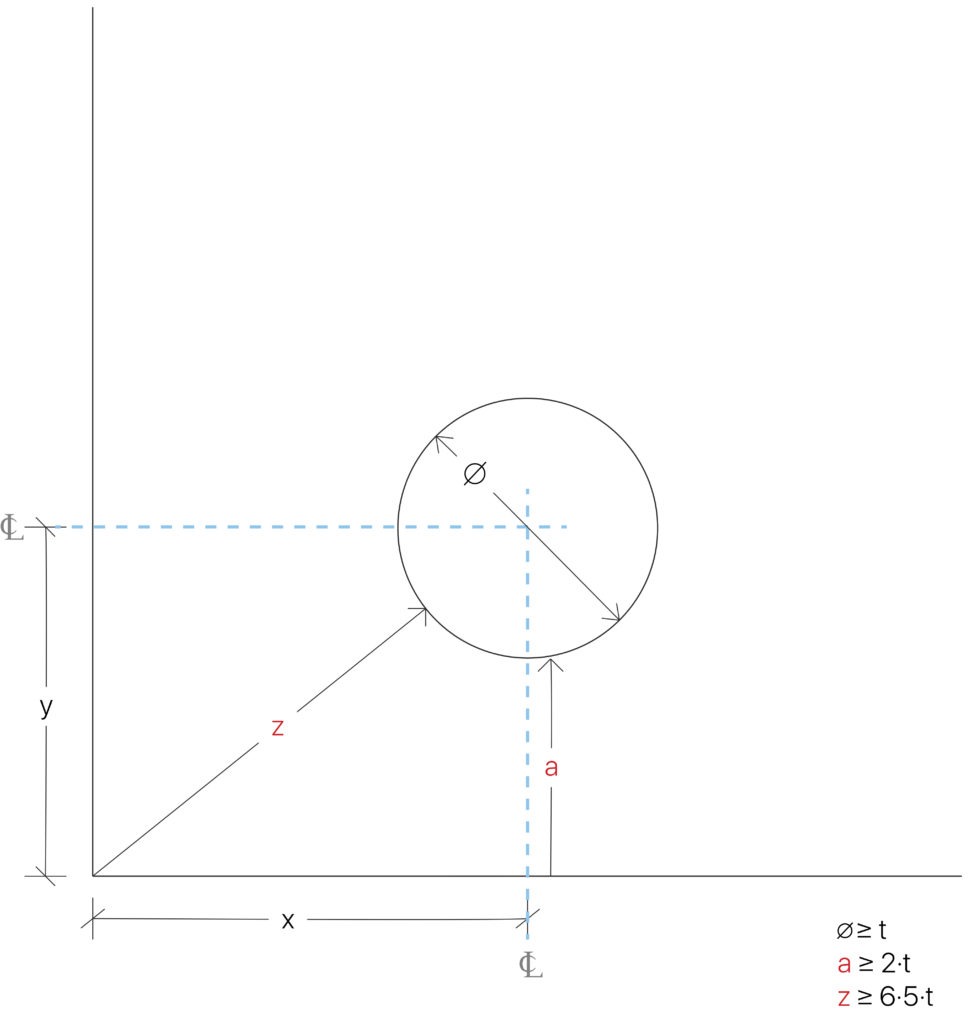

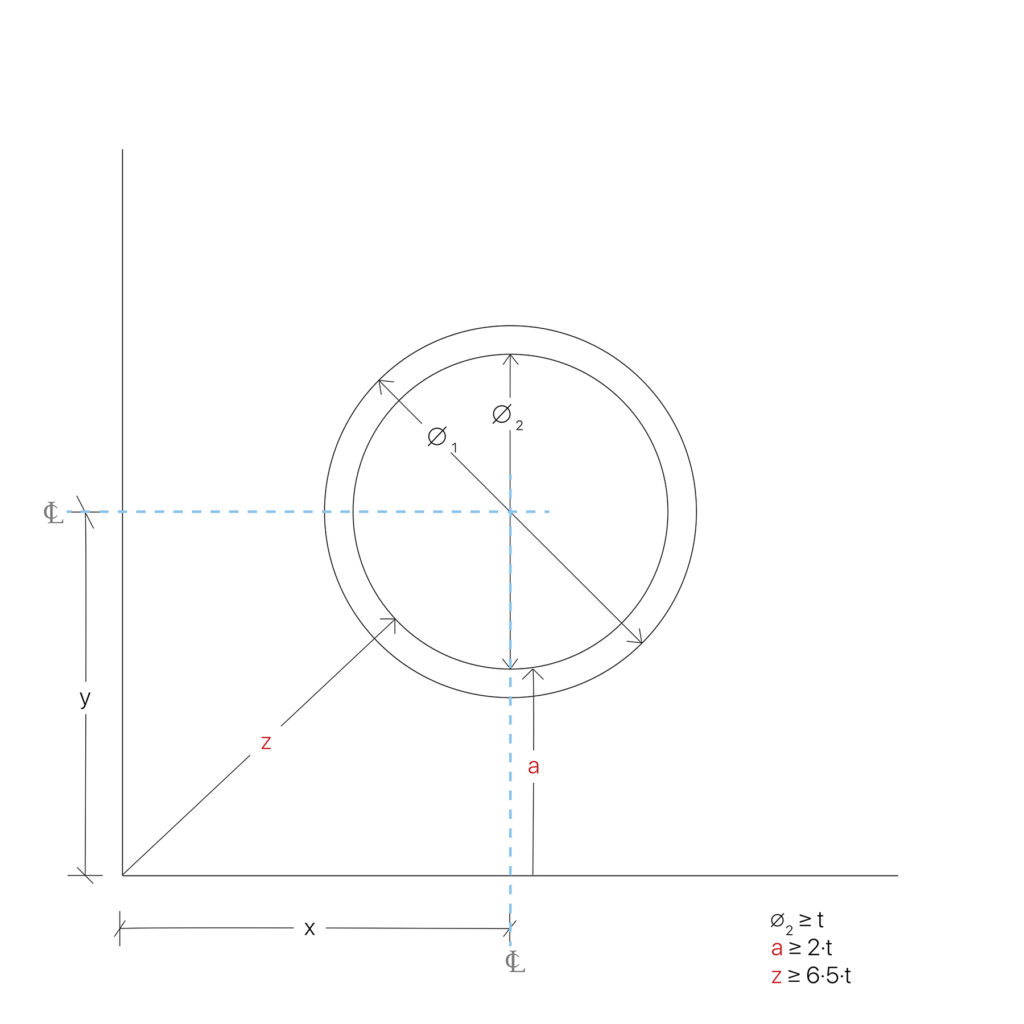

Countersunk Holes

- Available on glass thicknesses 1/4 in. (6 mm) and over

- Holes will have a ground finish arris.

- Countersunk holes require special attention and handling and must be reviewed with production prior to placing an order.

Relief Cut Hole

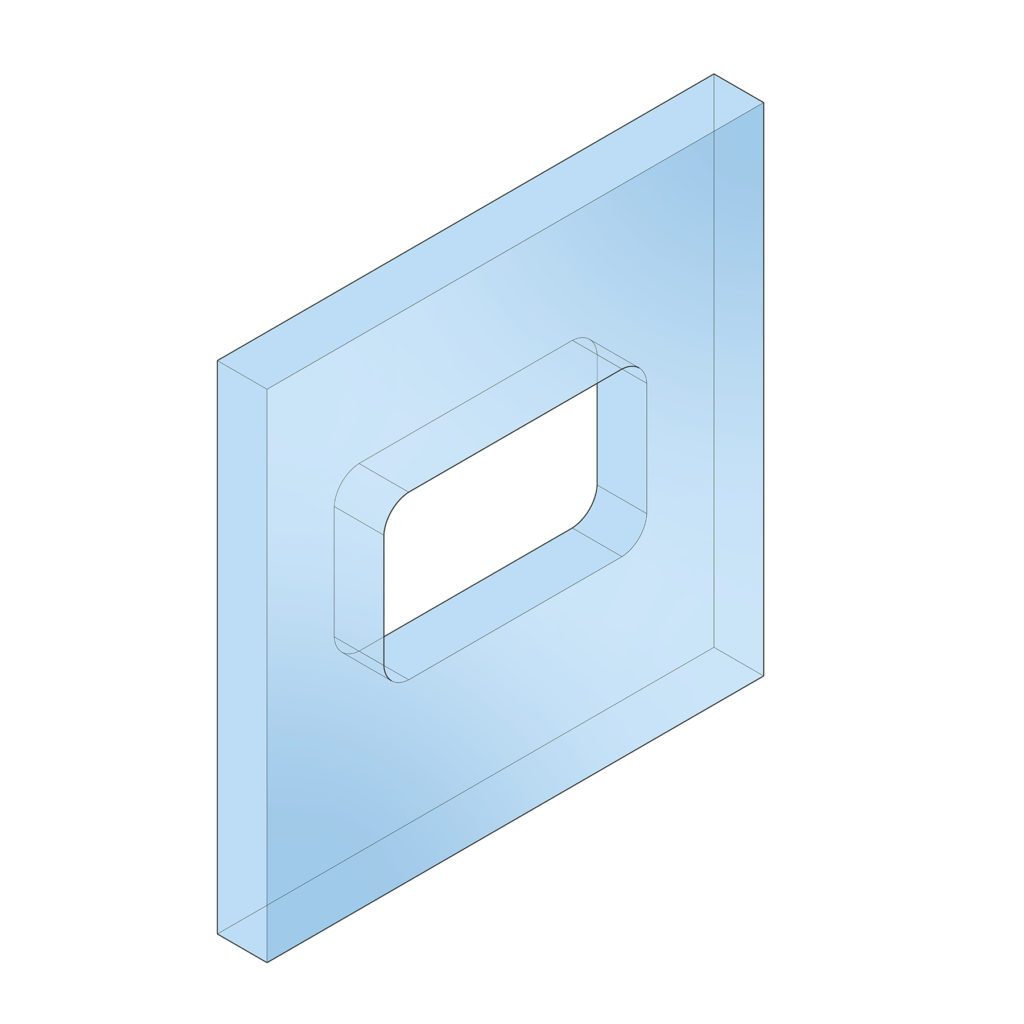

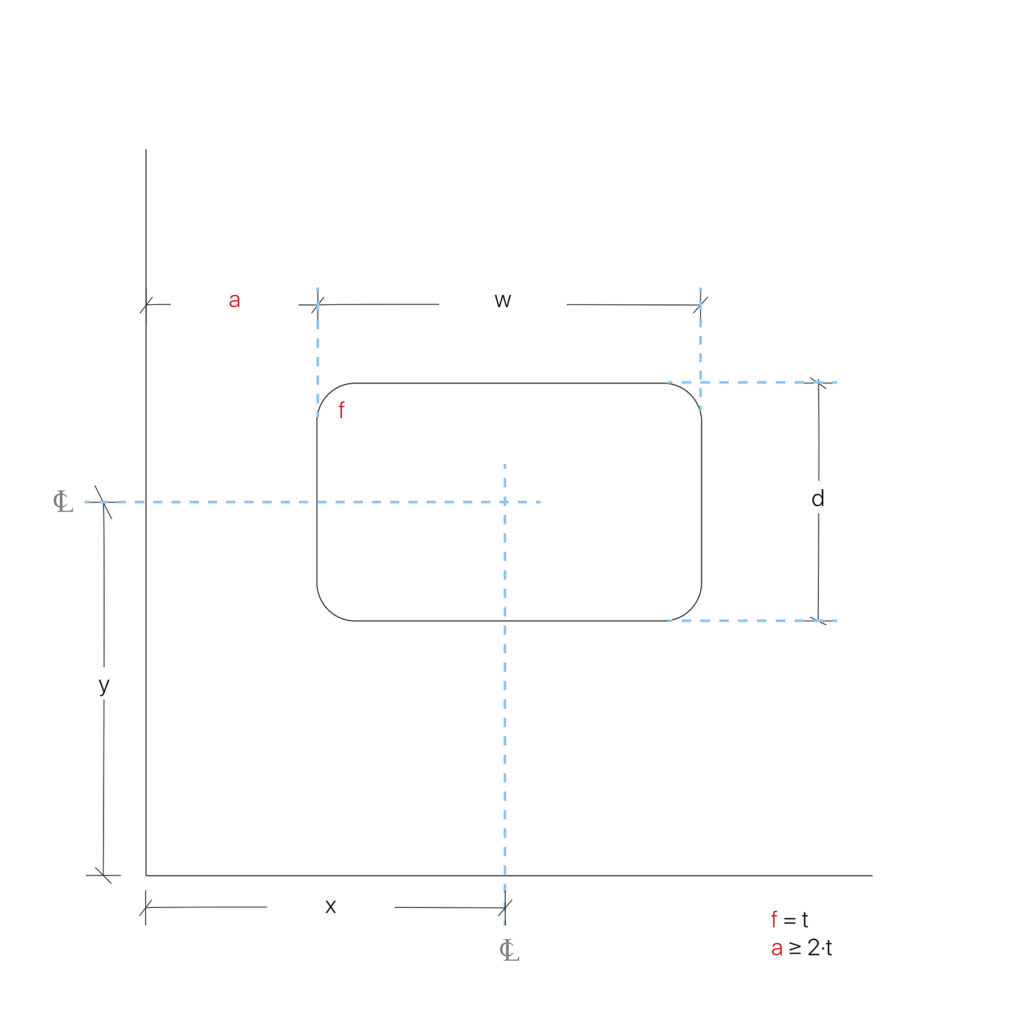

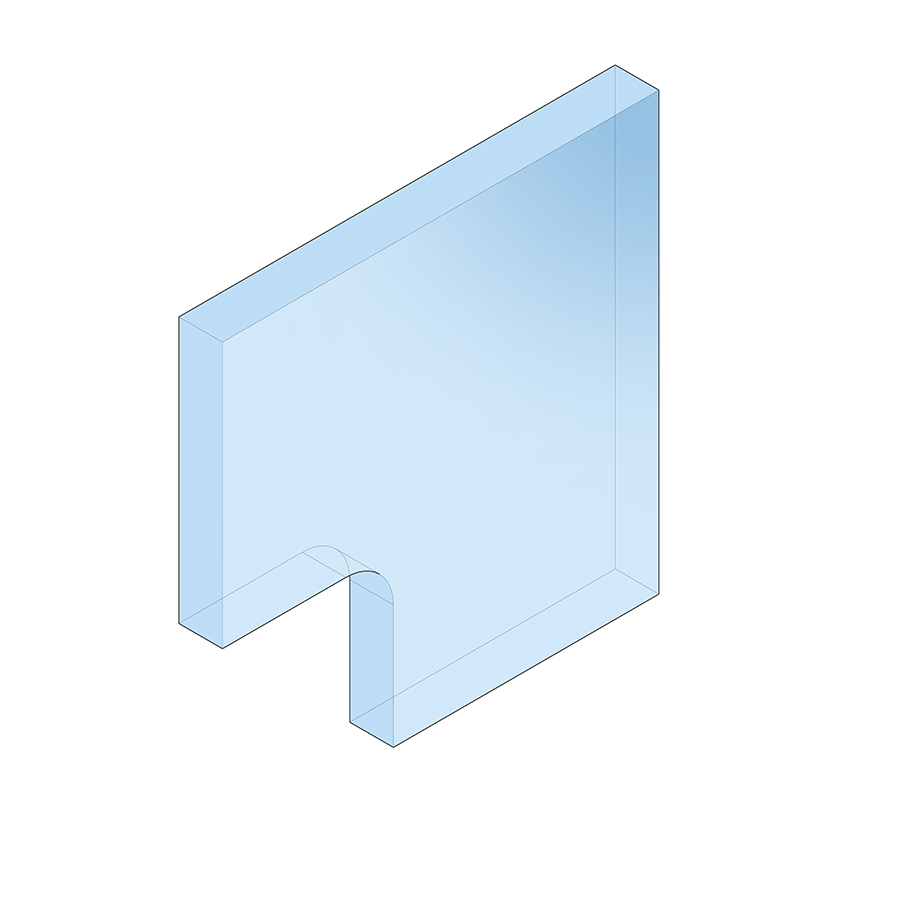

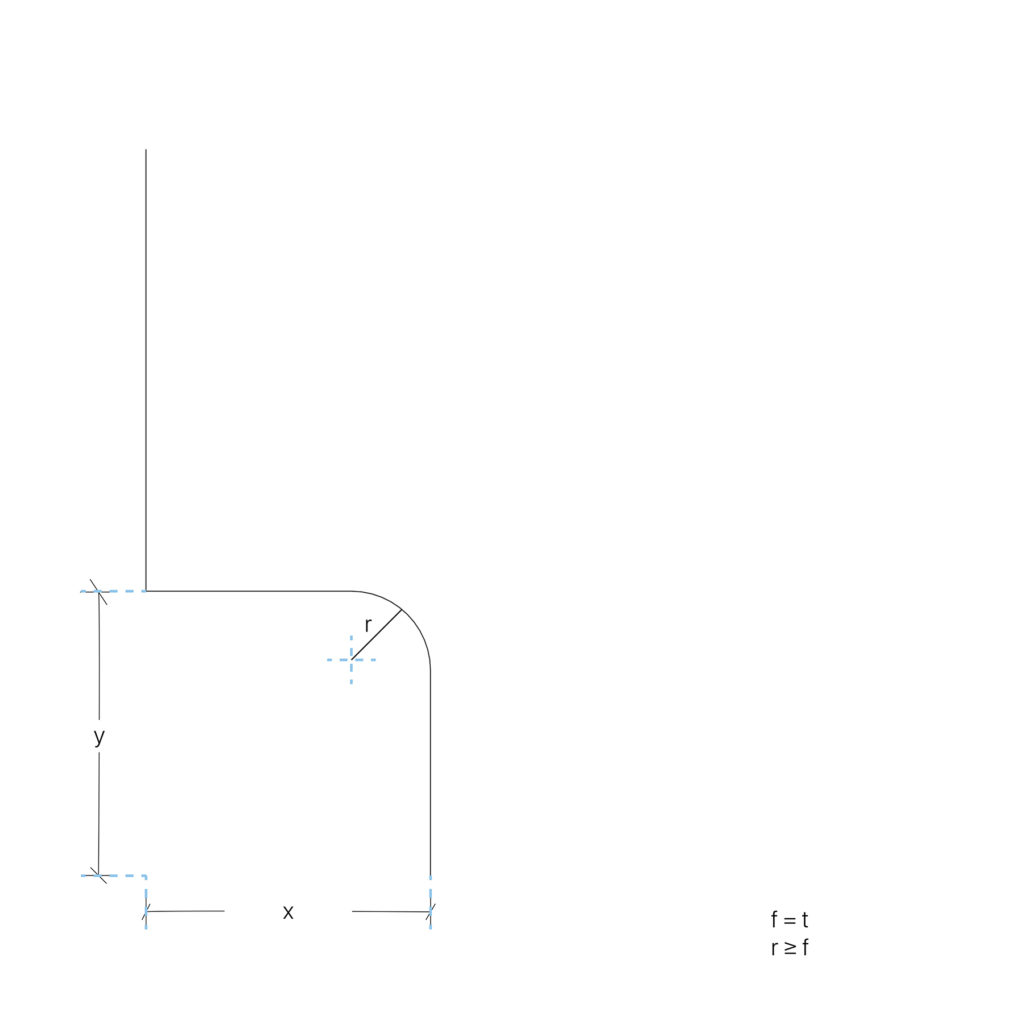

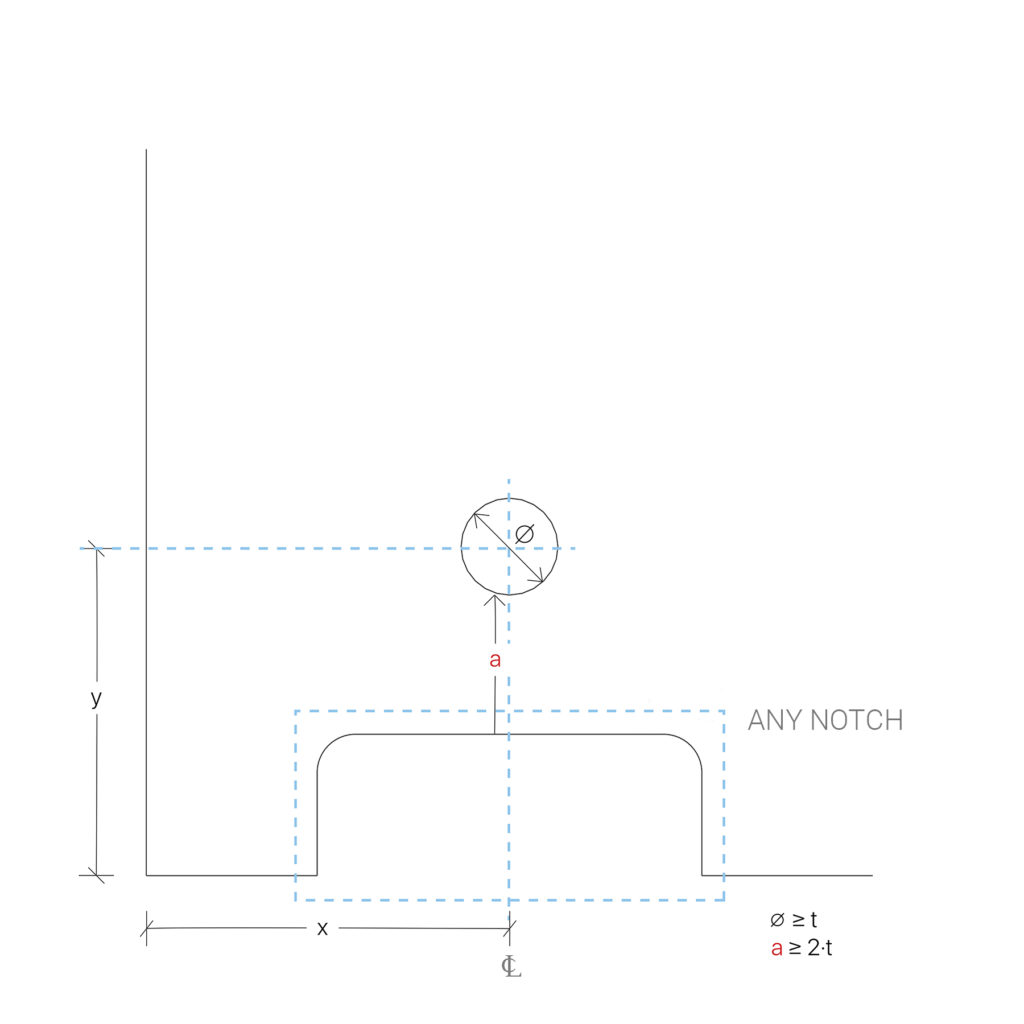

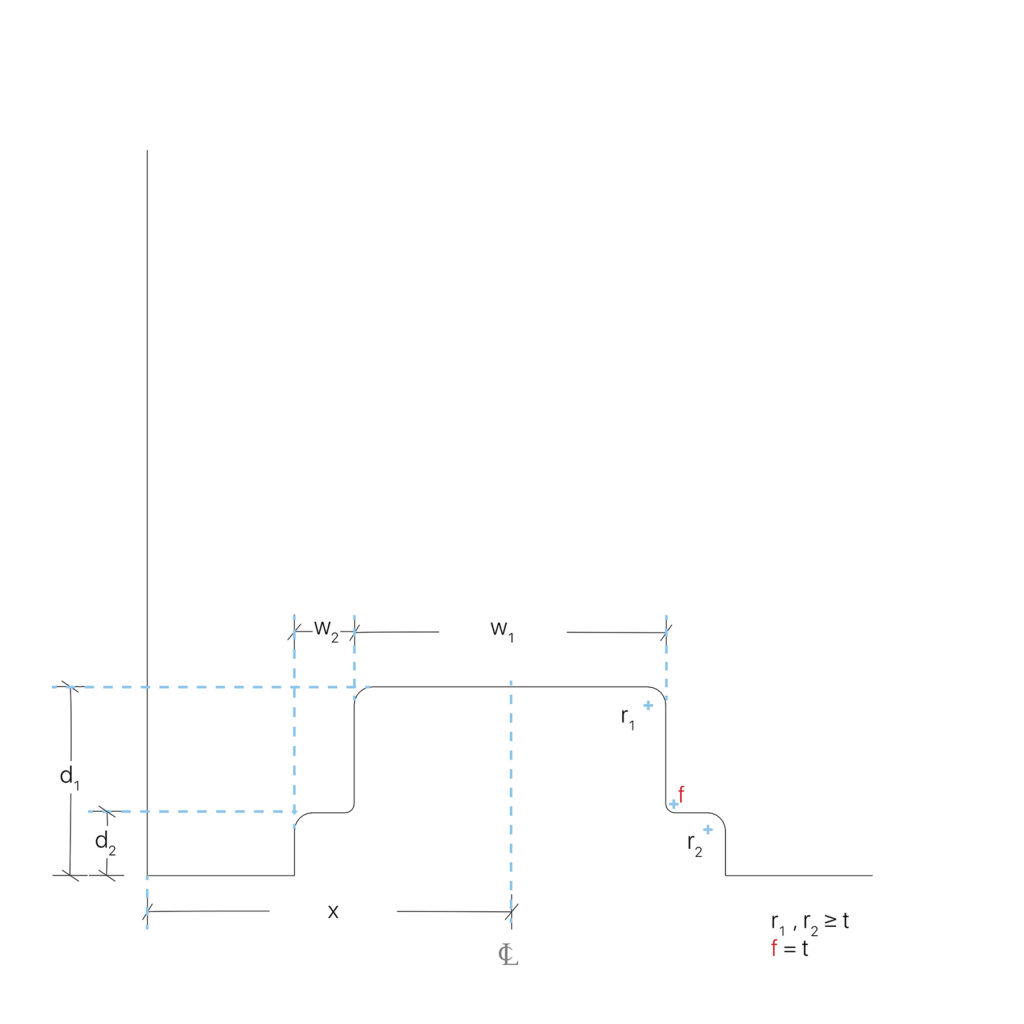

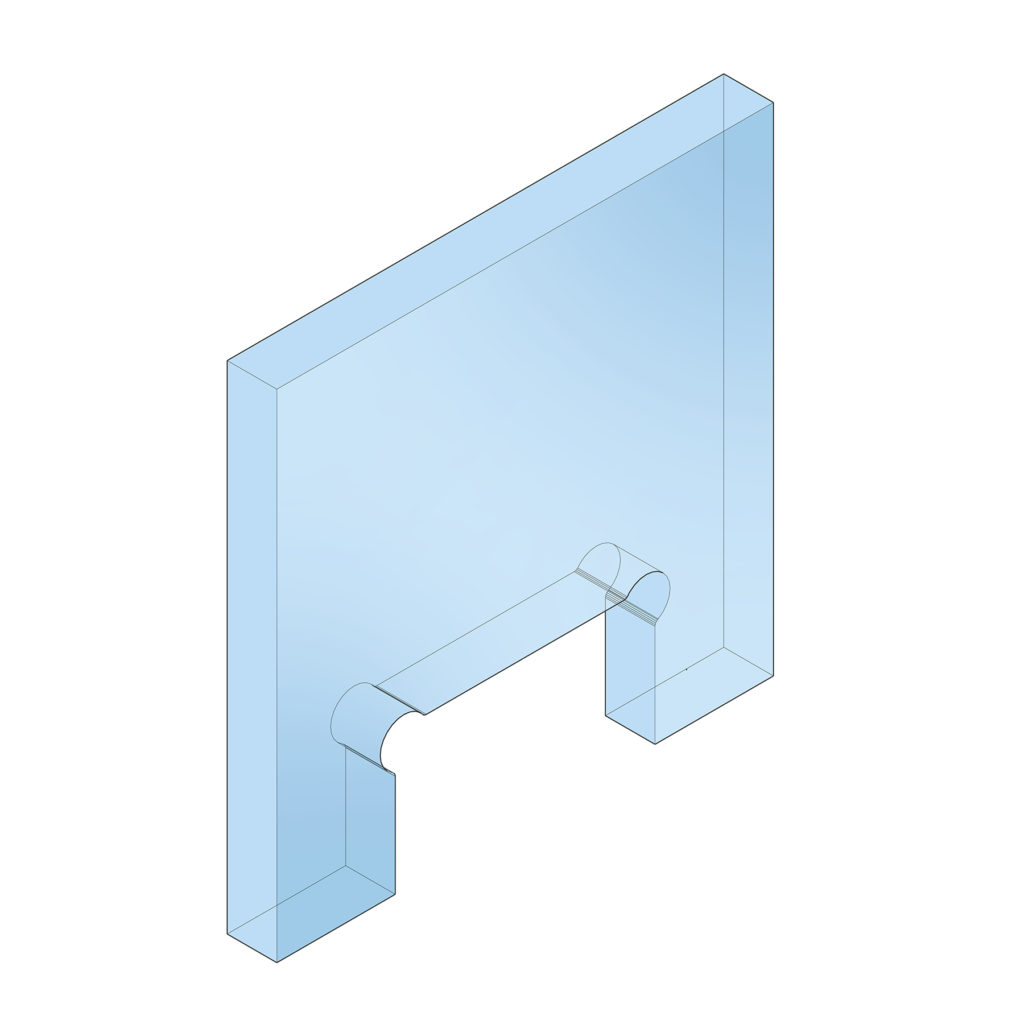

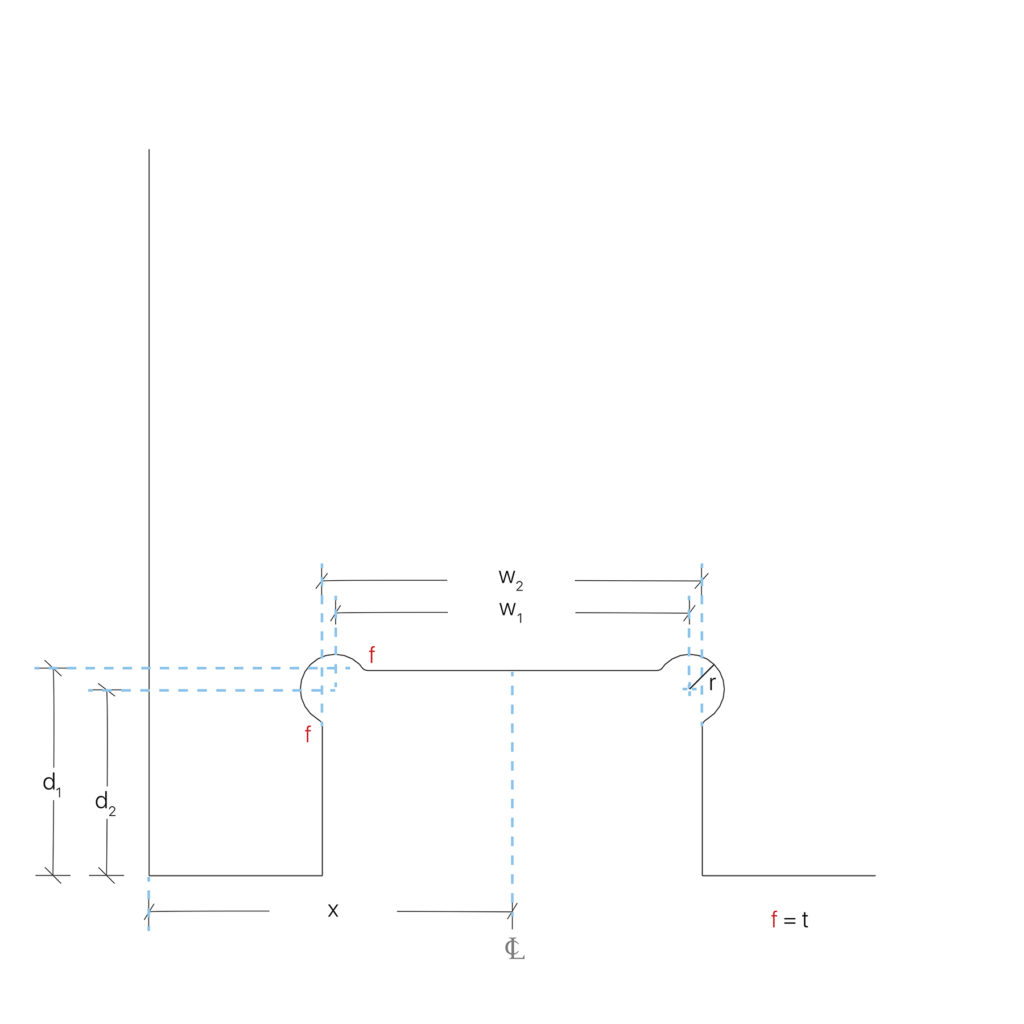

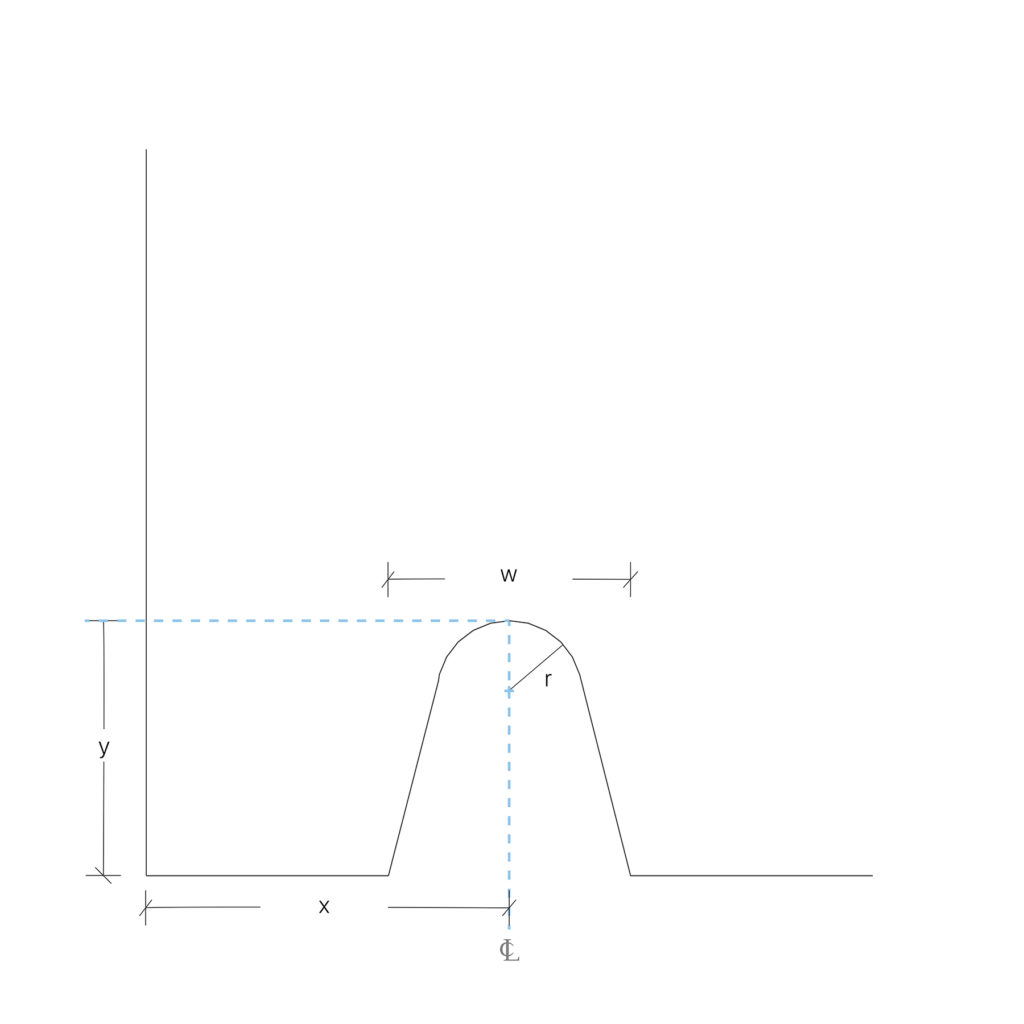

Rectangular Notch

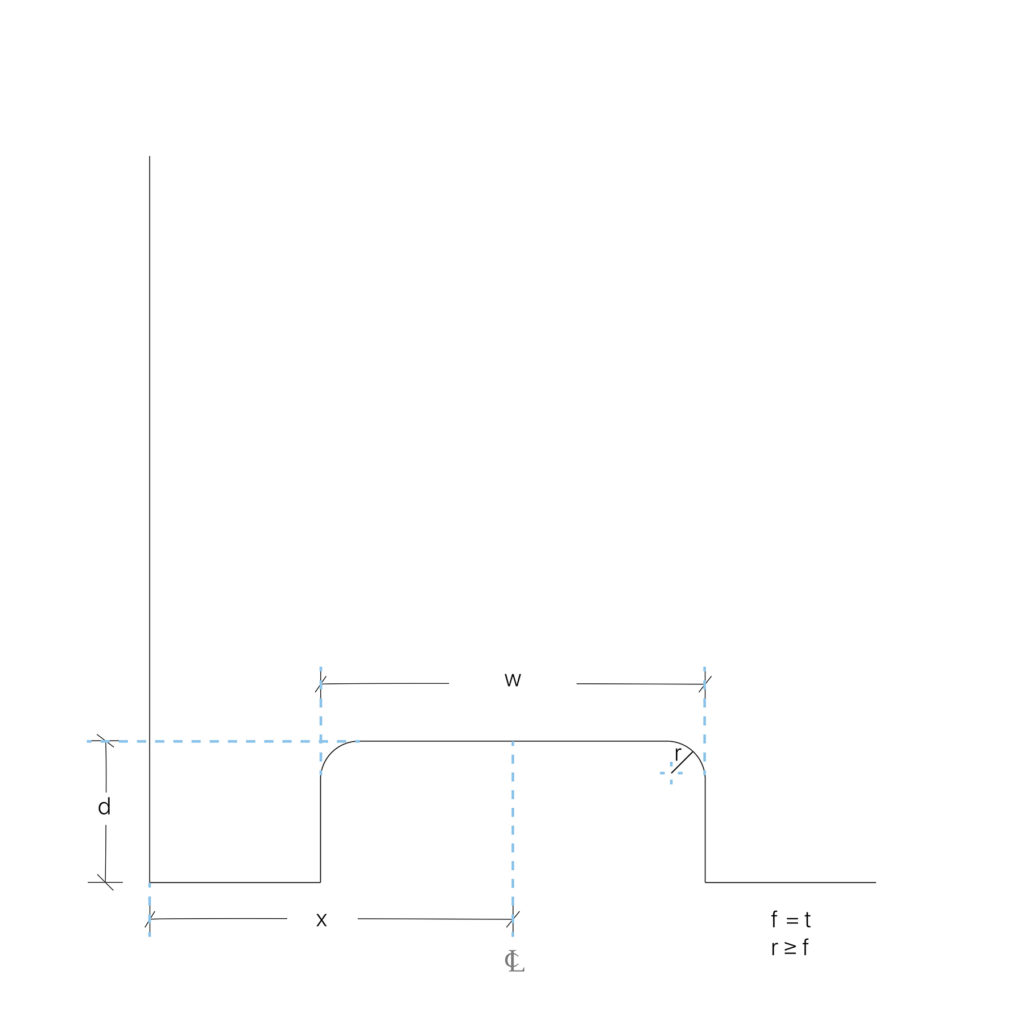

- The depth or width of the notch or cut-out cannot have a dimension larger than 1/3 of the narrowest dimension of the lite/panel.

- The leg length must be more than the depth of the notch.

- The leg length must be at least 3 in. (76.2 mm).

- The depth of the notch must be less than the width.

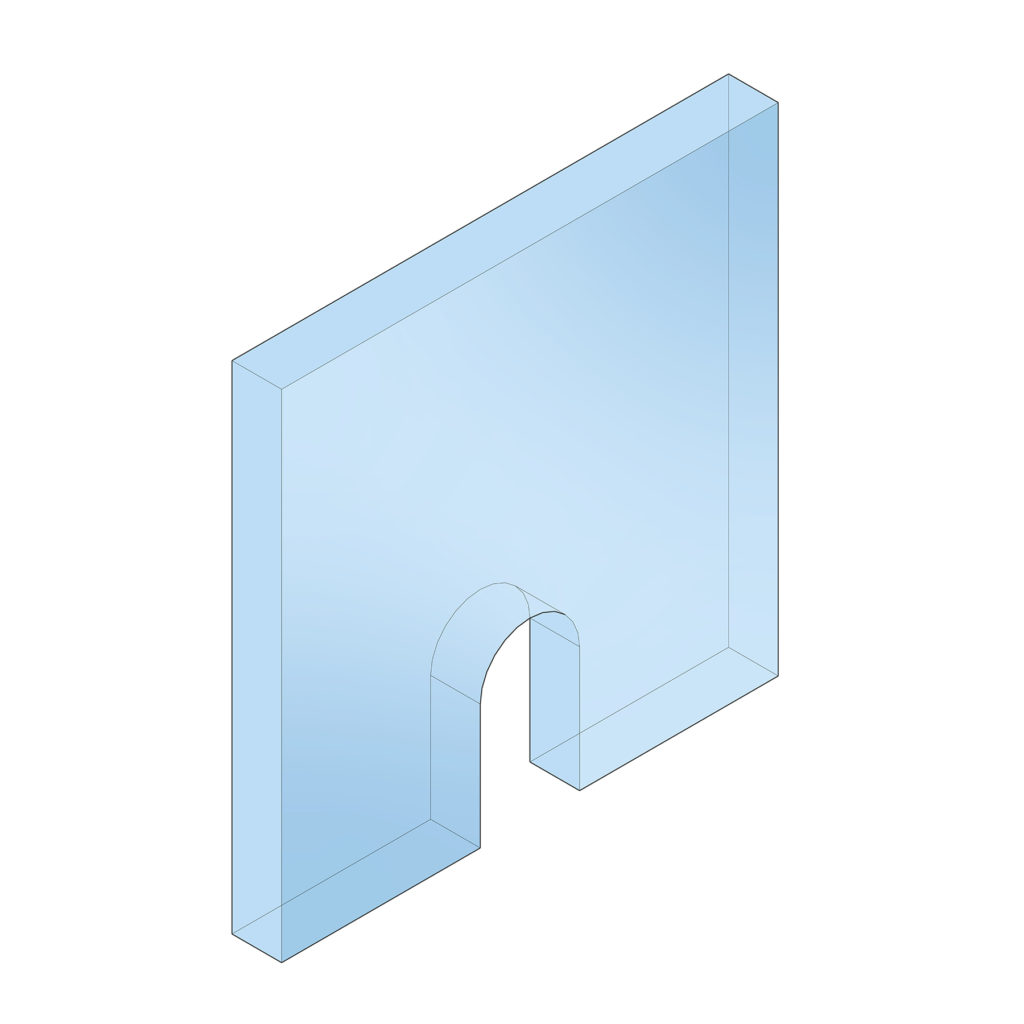

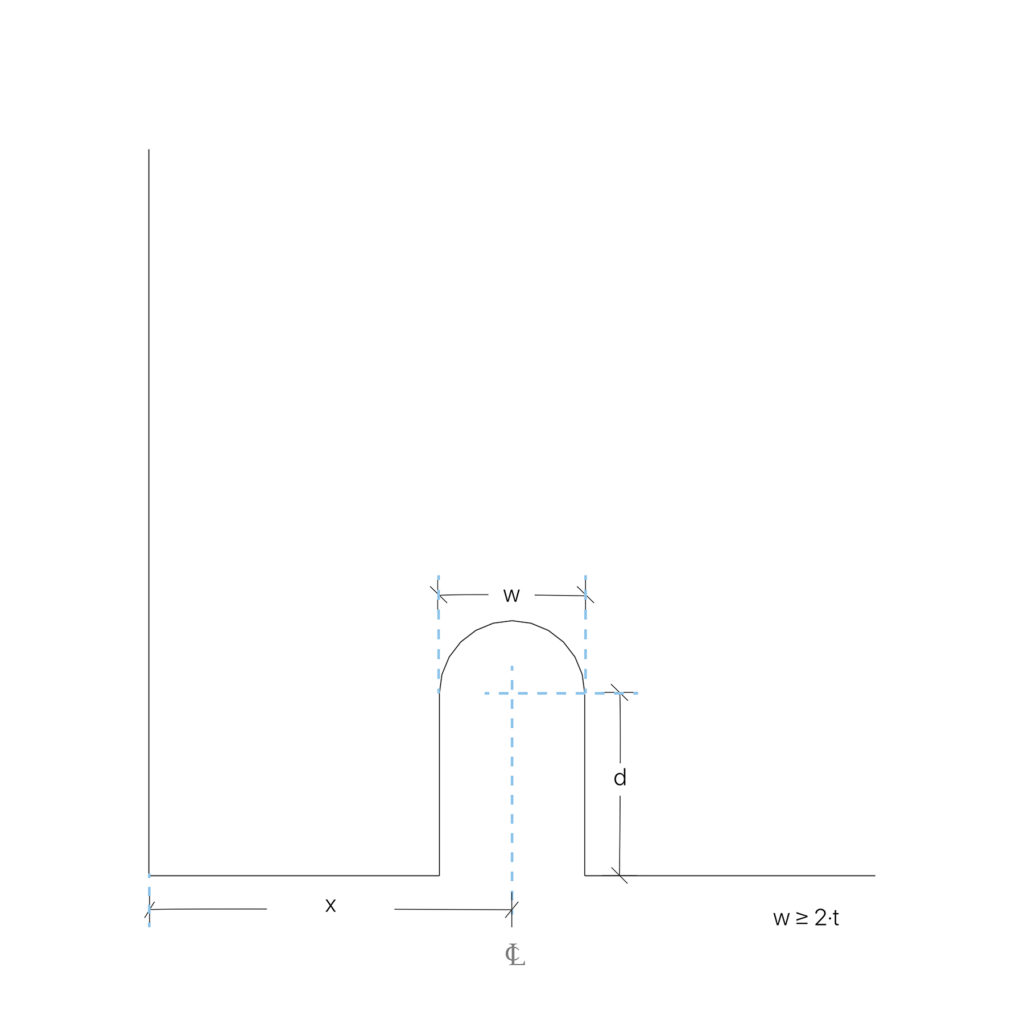

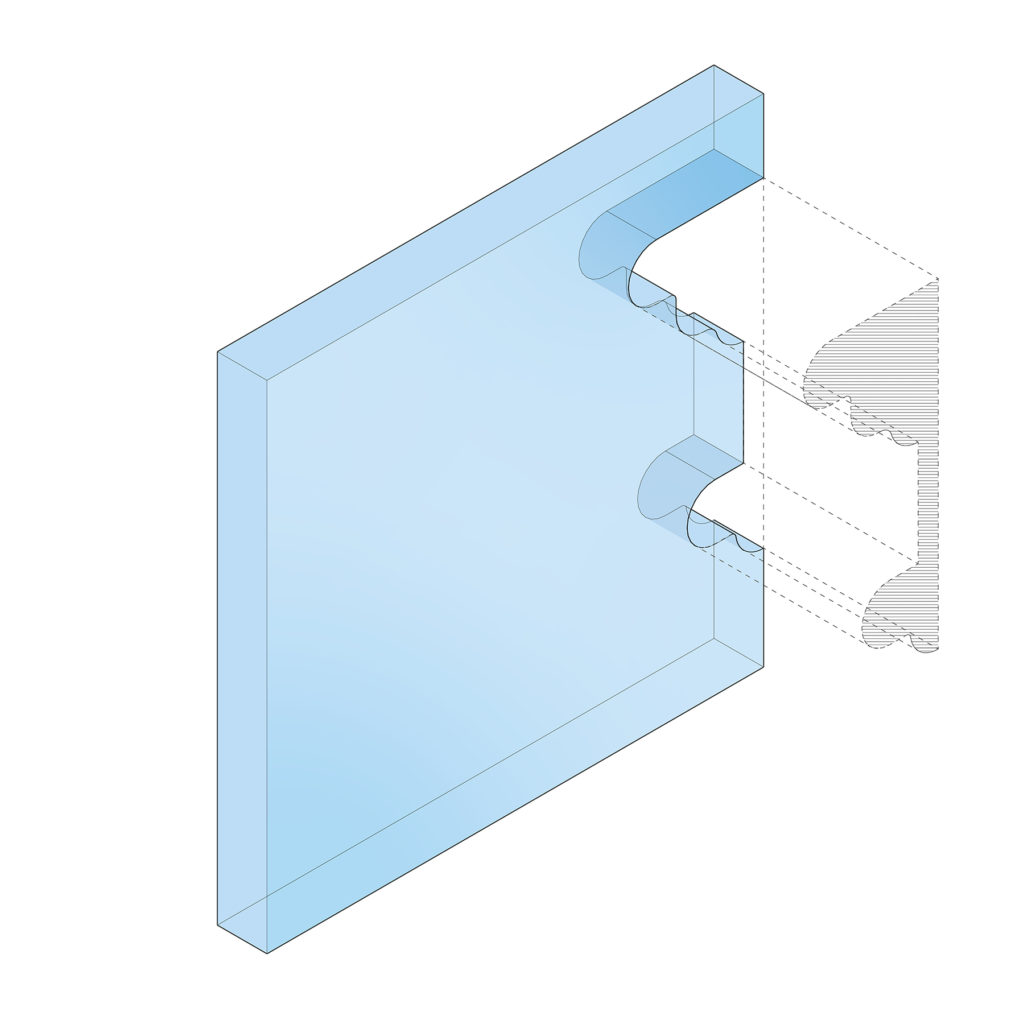

- The inside corner(s) must have a radius equal to, or greater than the thickness of the glass, but not less than 1/2 in. (12.7mm).

To provide you with notches and cut-outs, the corners must have fillets. A fillet is a rounded corner of which the straight edge emerges. The radius of the fillet must be equal to or greater than the thickness of the glass, but not less than 1/2 in. (12.7 mm).

Corner Notch

Full Notch

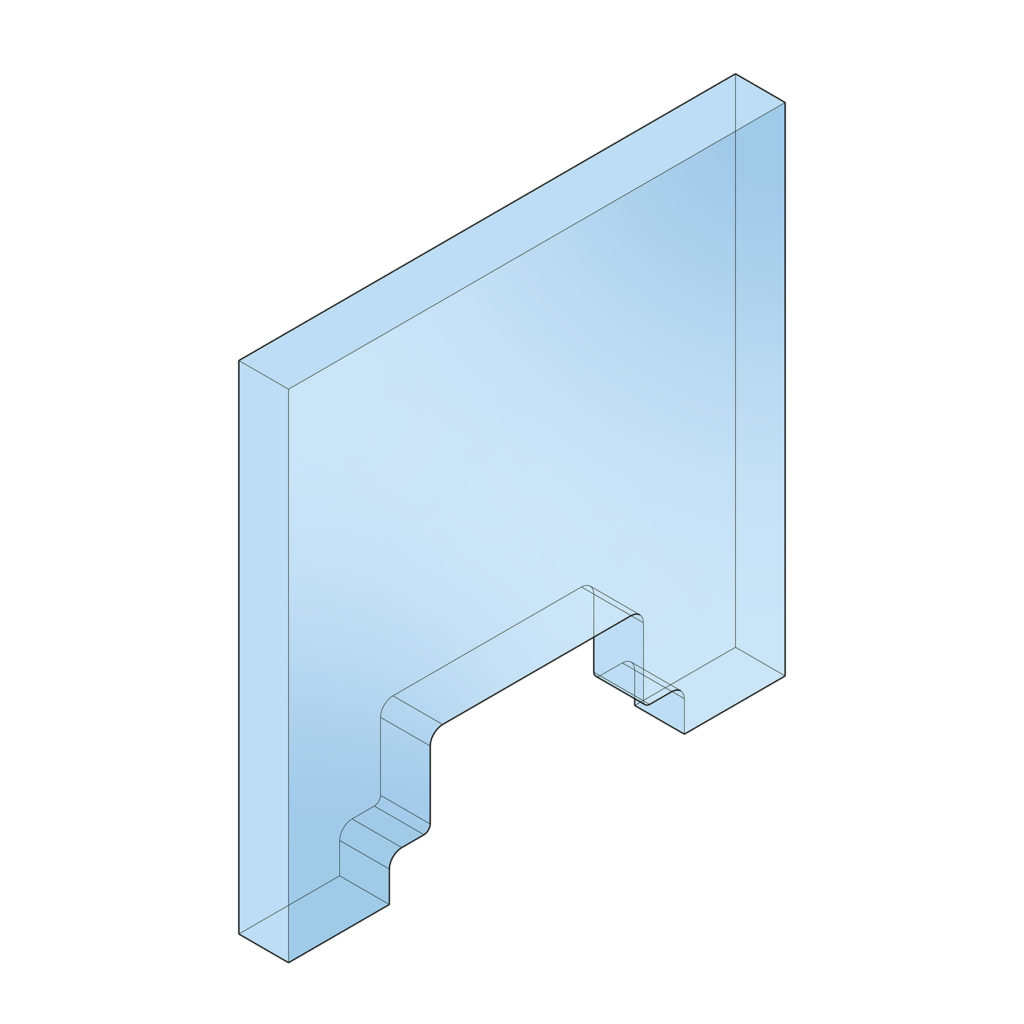

Notch with Drilled Hole

Notch with Shoulders

Mouse Ear Notch

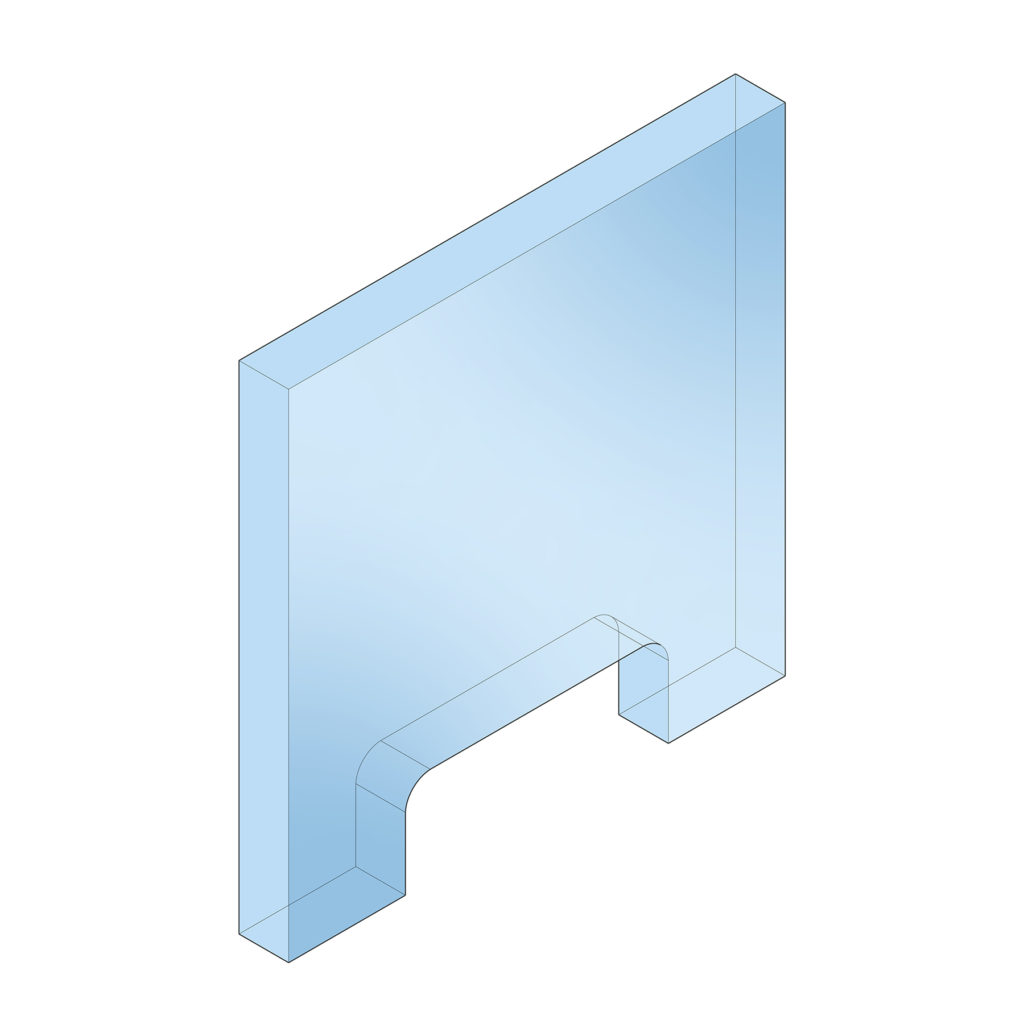

Finger Notch

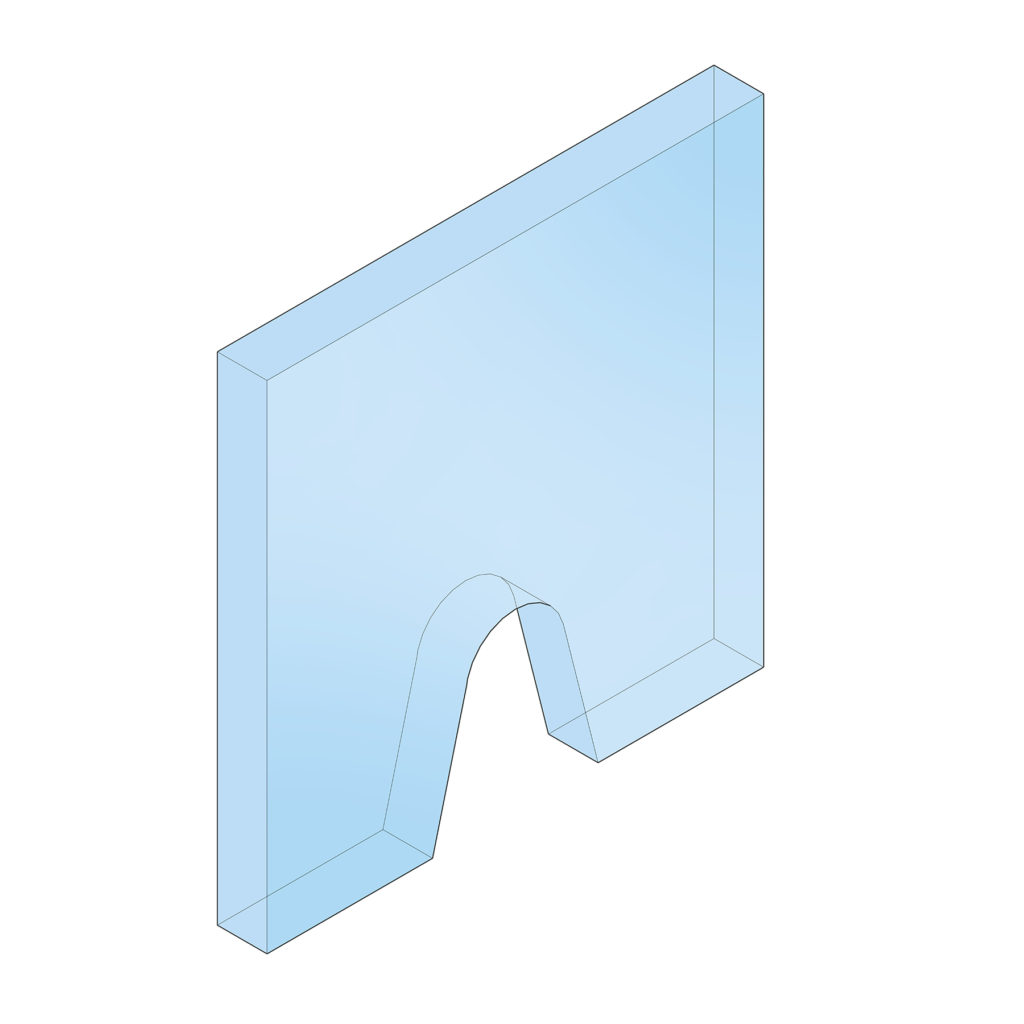

Hill Notch

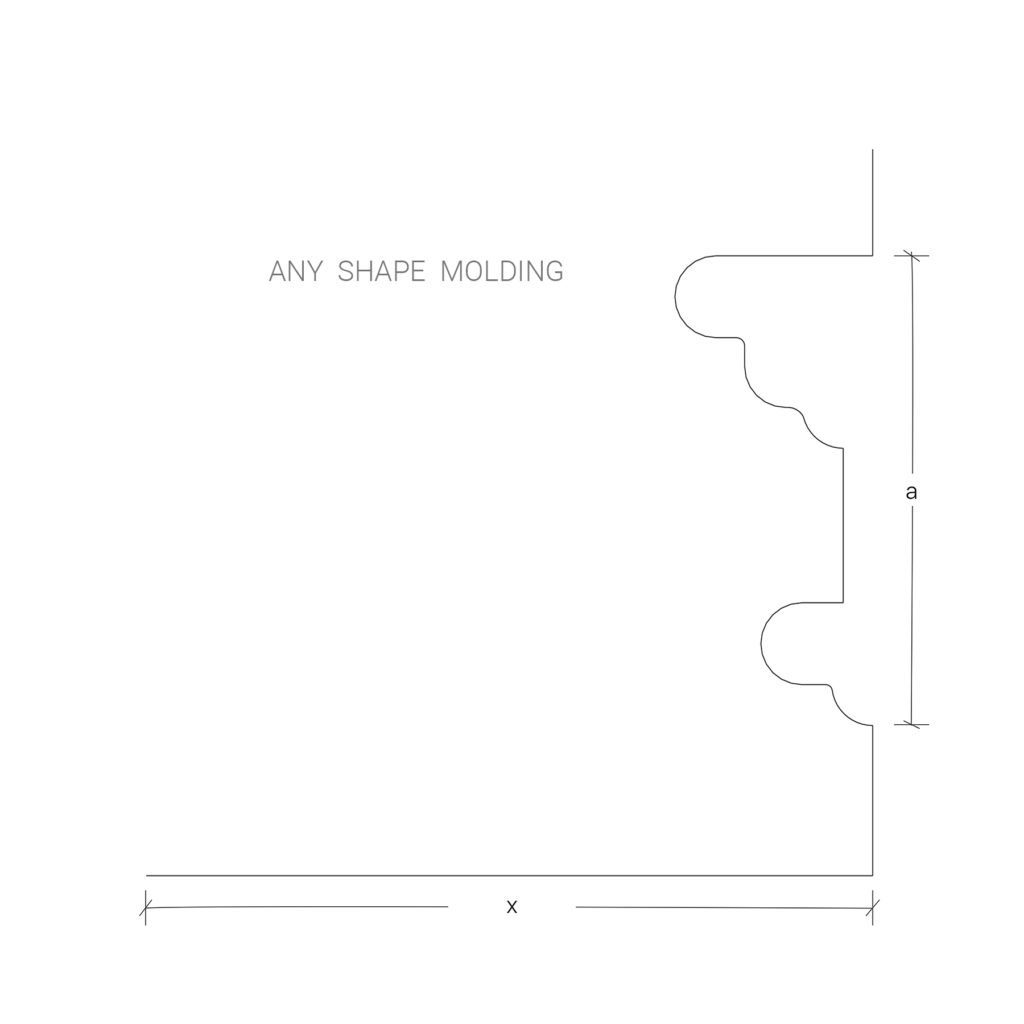

Custom Notch

Corners

Square Corner

Dubbed Corner

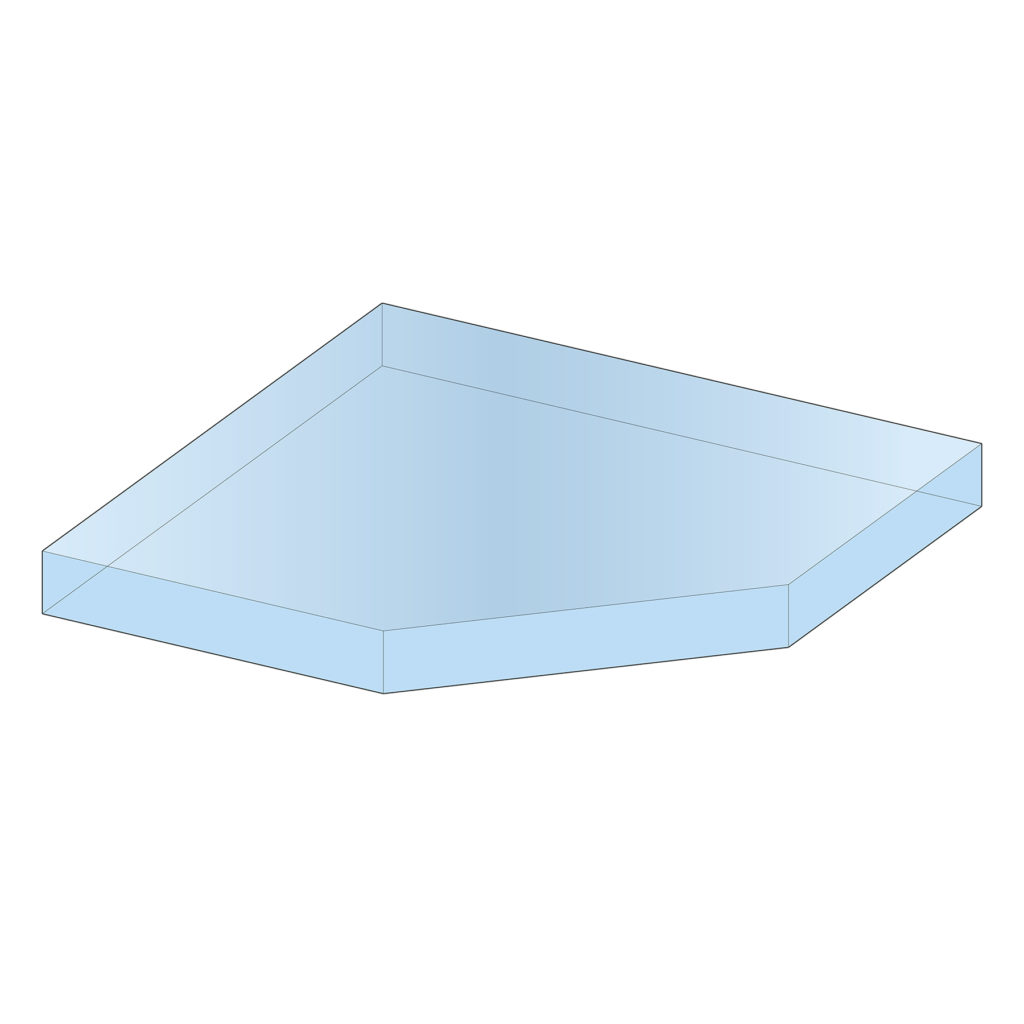

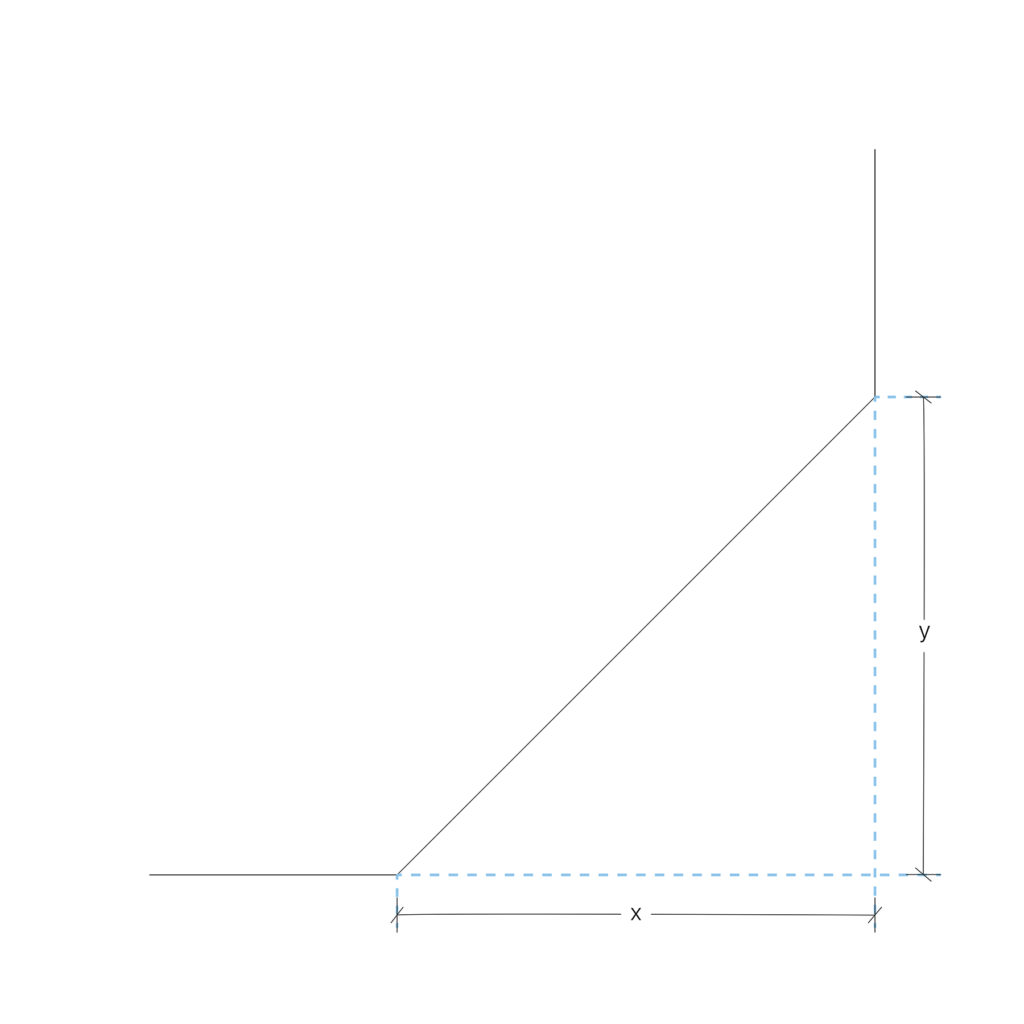

Clipped Corner

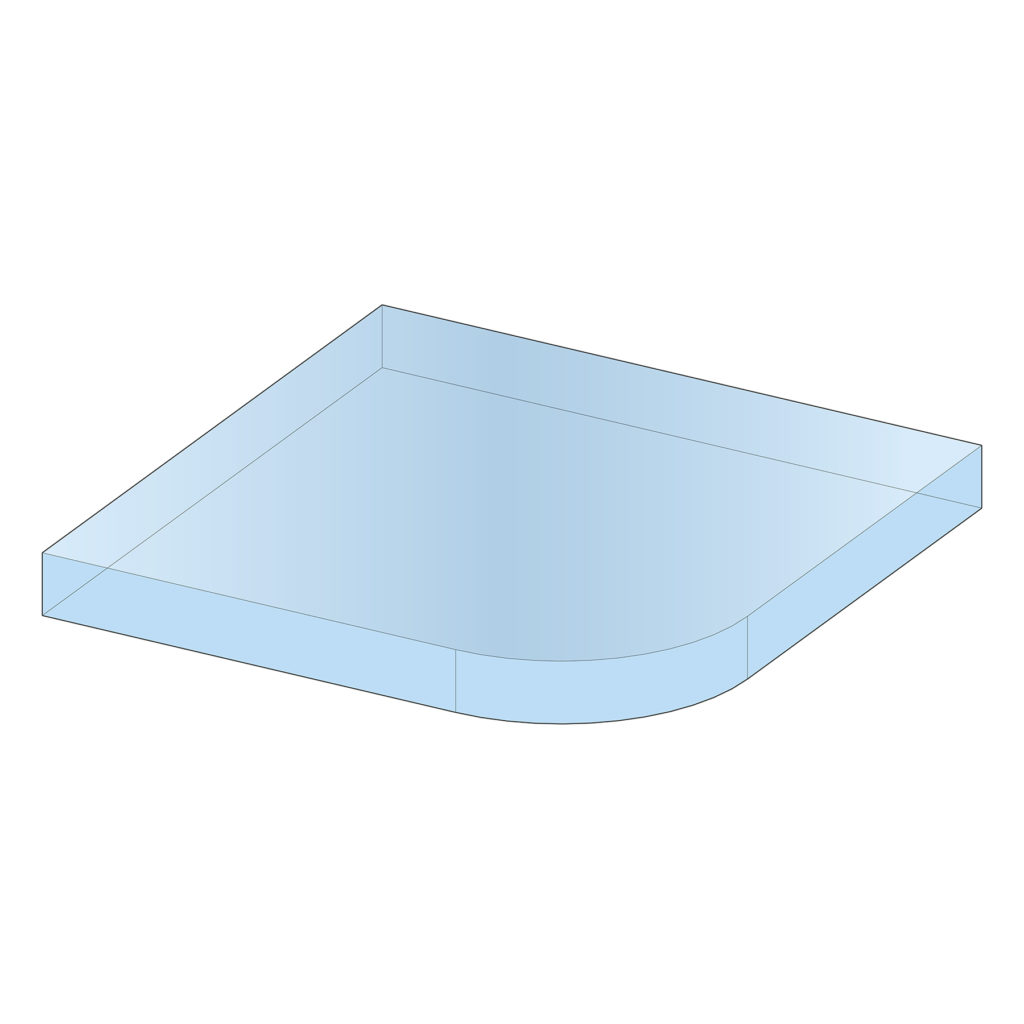

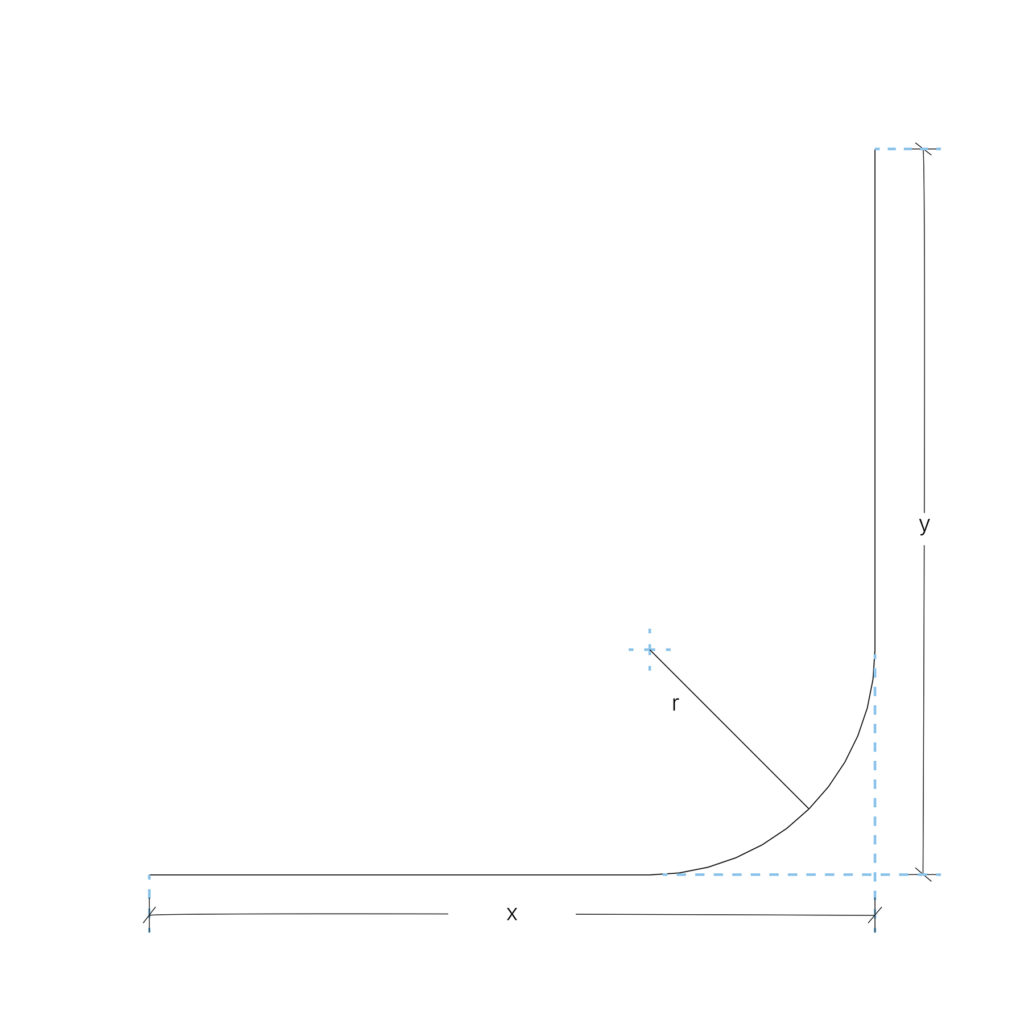

Radiused Corner

get INSPIRED!

Please note: The information contained in this website is offered for assistance in the application of Vectra Glass fabricated flat glass products, but it does not constitute a warranty of merchantability or fitness for any particular purpose. The actual performance of the products may vary in particular applications and installation methods and materials as set forth by the International Building Code.