![]()

Renewable energy

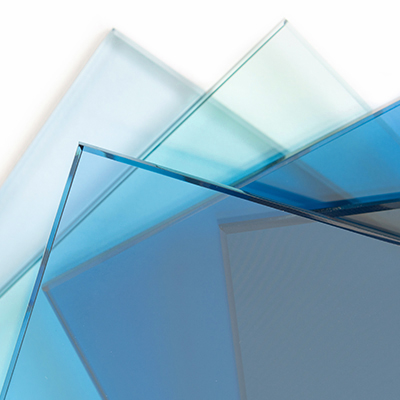

From ovens to cutting machines, glass manufacturing uses power. We adopted a triple net strategy of using solar energy to combat the environmental and economic costs. Our savings are passed on to the customer and the excess energy is returned to the grid to power other nearby manufacturers.

![]()

Water usage

Water is used in large quantities in glass manufacturing. From edge grinding to water jet, almost all mechanical processes in glass fabrication use water. We have a state-of-the-art water recycling system that captures and recycles all processing water.

![]()

Material recycling

Glass panels are cut from large sheets. Even though we optimize cuts to minimize waste, we’re still left with a large amount of glass we can’t use. This glass typically can’t be recycled through traditional facilities due to its composition. We collect our drops and send them to be reused as cullet.